Design

New designs are engineered quickly and reliably between product design, mould design and production moulding in a seamless process by ensuring optimum communication through the development, tooling and production process.

A design brief is prepared using sketches or electronic data provided by the customer and timescales are agreed.

Our CAD systems can import and export electronic design data supplied by the customer. The most popular formats are IGS, Parasolid x_b/x_t and step.

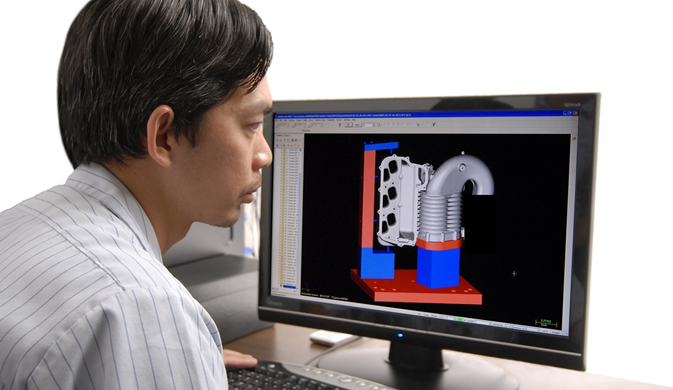

Design and development is carried out in a 3D CAD environment because it enables us to take your concept and transform it into a viable product eliminating many of the pitfalls encountered with traditional 2D CAD.

The 3D modelling process enables the product to be viewed in photorealistic clarity allowing any modifications to be made before the manufacture of the tooling. Electronic image files can be transferred to the customer allowing us to communicate globally.

Once the concept has been approved it is possible to interrogate the 3D model or assembly for physical properties and check for interference and fit.

The electronic data is used to produce SLA, SLS or vacuum moulded rapid prototypes as well as CNC cutter paths for producing the mould.

Dimensioned 2D drawings will be supplied if required.

The design data is used to design the mould tool on completion of verification and validation of the product design.

BENEFITS

- Product designs are engineered quickly, reliably and without fuss from a design brief which has been agreed with the customer.

- Assemblies are analysed for interferance between parts.

- Components can be visualised and prototypes produced direct from the CAD data.

- The same data is used by product and tooling designers which eliminates errors.

Whether you're looking for expert advice, a prototype or a production run of any size, contact D&G Moulding today on +44 (0) 1420 549347 or email sales@dgmouldingltd.com